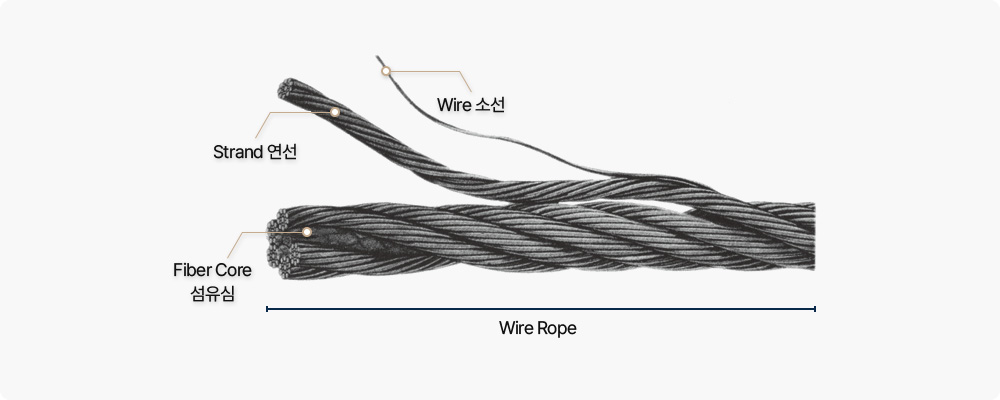

Basic information of Wire Rope

The name of the parts

composing wire rope

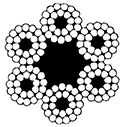

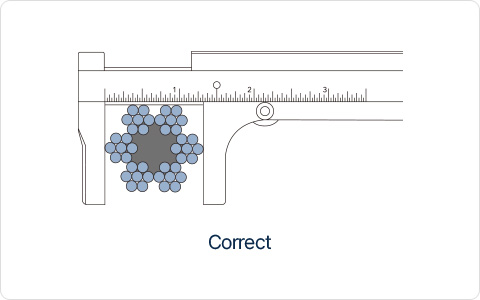

Wire Rope is consisted of Core and several Strands surrounding the Core

Number of Strands differs according to

the constitution but 3~8 in general, and the number

of Wire which consists strand differs according to

the use of wire rope